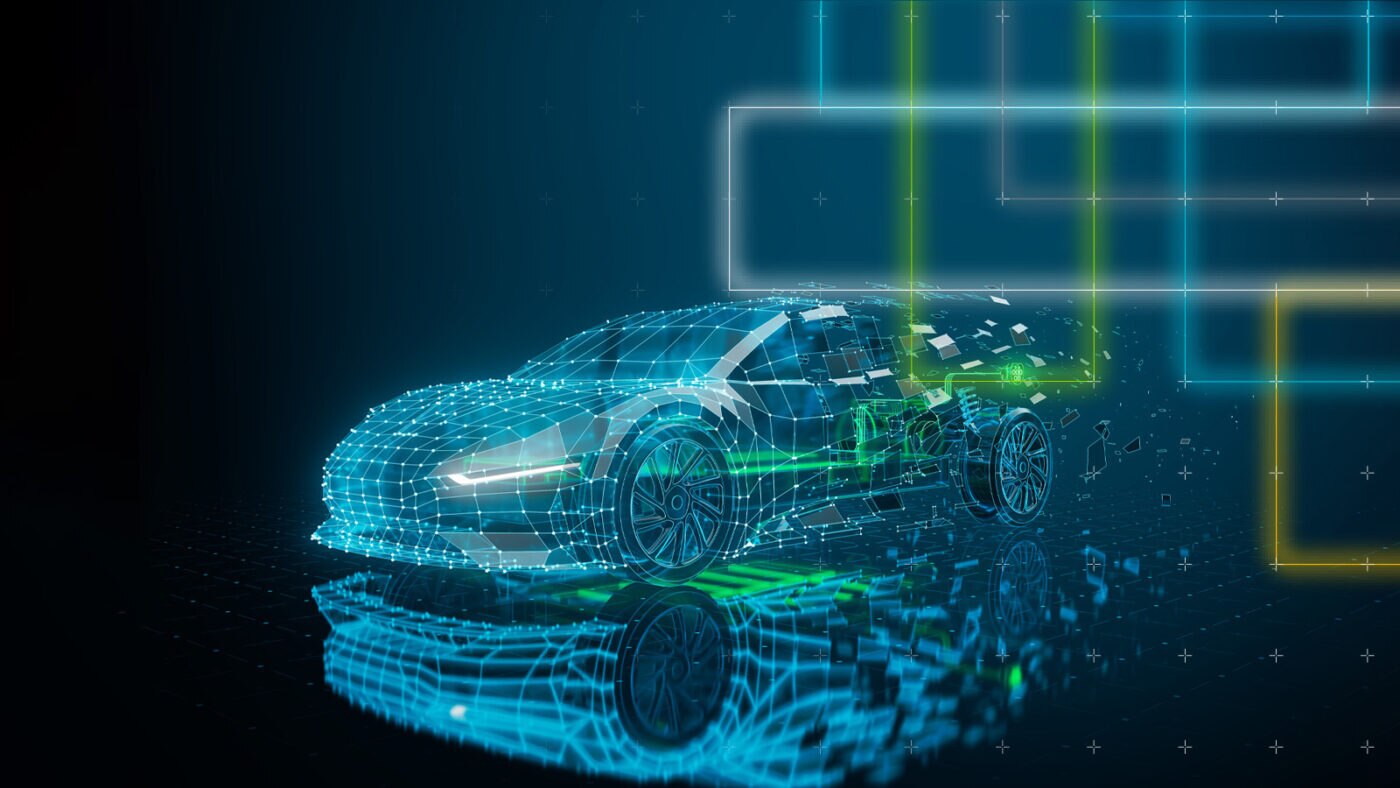

Creating a digital twin for the automobile industry involves integrating advanced technologies like IoT, AI, data analytics, and 3D modelling to create a virtual replica of a vehicle, production line, or even an entire automotive ecosystem. We will understand the steps involved in creating a digital twin for the automobile industry as below:

Step 1: Define the Scope and Objectives

Identify the Purpose: Determine what you want to achieve with the digital twin. Examples include:

- Vehicle performance monitoring

- Predictive maintenance

- Manufacturing process optimization

- Design and testing of new vehicle models

Scope: Decide whether the digital twin will represent a single component, a full vehicle, or an entire production facility.

Step 2: Collect Data from the Physical Entity

Sensors and IoT Devices: Install sensors on the physical vehicle or production line to collect real-time data. Examples include:

- Engine temperature, pressure, and vibration sensors

- GPS and telematics for vehicle tracking

- Production line sensors for monitoring machinery performance

Historical Data: Gather existing data from past operations, maintenance logs, and design specifications.

Step 3: Develop the Virtual Model

- 3D Modeling: Create a detailed 3D model of the vehicle or component using CAD (Computer-Aided Design) software.

- Simulation Tools: Use simulation software (e.g., ANSYS, MATLAB, or Siemens NX) to replicate the physical behaviour of the vehicle or system. We can also explore the NVIDIA Physical AI platform to simulate the real-world behaviour.

- Data Integration: Connect the virtual model to real-time data streams from sensors and IoT devices.

Step 4: Implement Data Analytics and AI

- Data Processing: Use cloud platforms (e.g., AWS, Azure, or Google Cloud) to store and process large volumes of data.

- Machine Learning: Train AI models to analyze data, predict outcomes, and optimize

performance. For example:

- Predict engine failures based on sensor data.

- Optimize fuel efficiency using driving patterns.

- Real-Time Monitoring: Set up dashboards to visualize data and monitor the digital twin in real time.

Step 5: Establish Connectivity and Communication

IoT Platforms: Use IoT platforms (e.g., Siemens MindSphere, PTC ThingWorx) to connect physical assets with the digital twin.

Edge Computing: Implement edge computing for low-latency data processing, especially for critical operations like autonomous driving.

Step 6: Validate and Test the Digital Twin

- Simulation Testing: Run simulations to ensure the digital twin accurately reflects the physical entity.

- Real-World Testing: Compare the digital twin’s predictions with actual performance data to validate its accuracy.

- Iterate: Continuously refine the digital twin based on feedback and new data.

Step 7: Deploy and Scale

- Pilot Project: Start with a small-scale implementation, such as a single vehicle or production line.

- Scale Up: Gradually expand the digital twin to cover more vehicles, components, or processes.

- Integration: Integrate the digital twin with other systems, such as ERP (Enterprise Resource Planning) or CRM (Customer Relationship Management).

Step 8: Monitor, Maintain, and Optimize

- Continuous Monitoring: Use the digital twin to monitor performance and detect anomalies in real time.

- Predictive Maintenance: Schedule maintenance based on predictive insights from the digital twin.

- Optimization: Continuously optimize processes, designs, and operations using insights from the digital twin.

Use Cases in the Automobile Industry

- Vehicle Design and Testing:

- Simulate vehicle performance under different conditions (e.g., crash tests, aerodynamics).

- Test new designs virtually before building physical prototypes.

- Predictive Maintenance:

- Monitor vehicle components (e.g., brakes, engine) to predict failures and schedule maintenance.

- Manufacturing Optimization:

- Monitor production lines to identify bottlenecks and improve efficiency.

- Simulate changes to the production process before implementation.

- Autonomous Vehicles:

- Use digital twins to simulate and test autonomous driving algorithms in virtual environments.

- Fleet Management:

- Track and optimize the performance of a fleet of vehicles in real time.

Challenges in Creating Digital Twins

- Data Quality: Ensuring accurate and reliable data from sensors and IoT devices.

- Integration: Connecting legacy systems with modern digital twin platforms.

- Cost: High initial investment in sensors, software, and infrastructure.

- Security: Protecting sensitive data and ensuring cybersecurity.

By following these steps and leveraging the right technologies, automotive companies can create digital twins that drive innovation, improve efficiency, and reduce costs across the entire product lifecycle.

Accelerate Your Automotive Innovation

Ready to build the future of mobility? Discover how Blocktwin's digital twin solutions can transform your automotive operations.

Contact Us